Guide: The textile company in Pakistan established a cooperative relationship with Xinli Boiler for one 6-ton SZL series biomass fired steam boiler through market and online search.

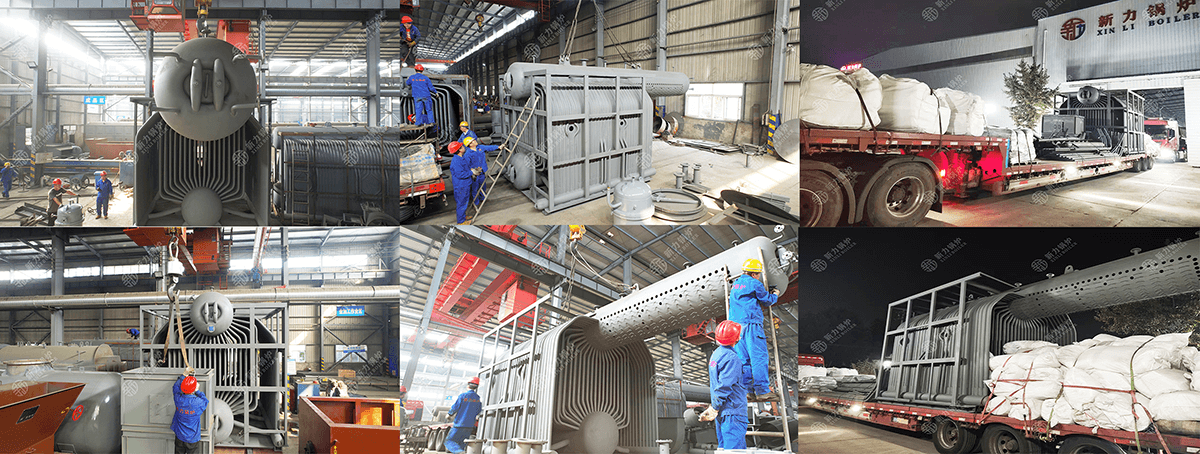

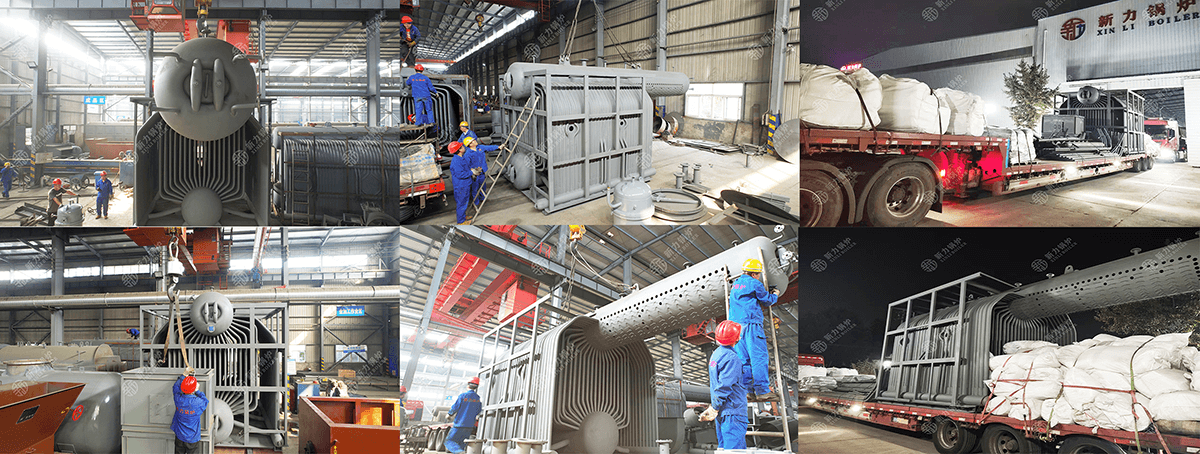

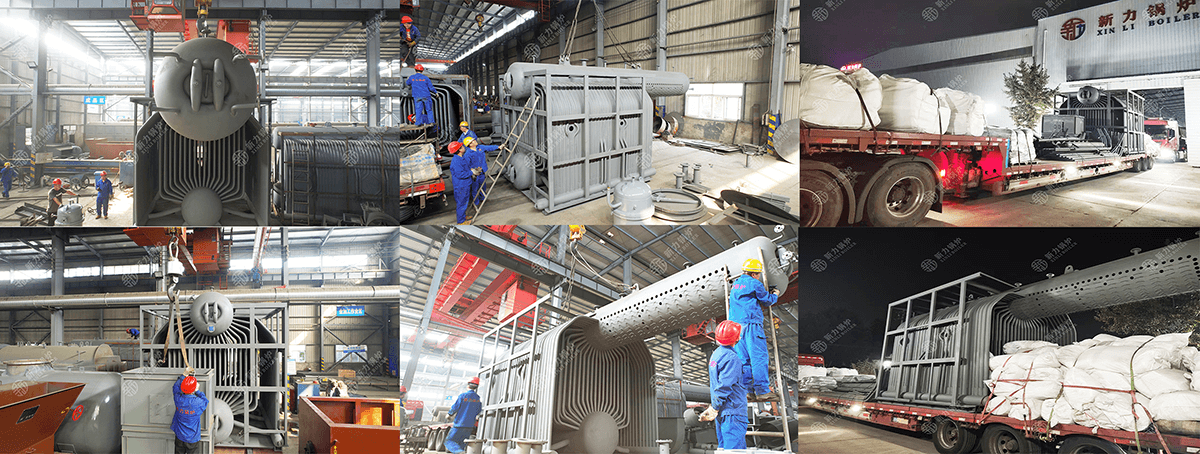

For textile enterprises, they cannot do without the support and cooperation of steam boilers whether it is dyeing, drying, sizing or printing and dyeing processes. Steam also helps maintain a stable temperature in the production environment, which is crucial for ensuring the quality of textiles. Due to the high fuel consumption of the textile industry ,this enterprise cooperating with Xinli Boiler aims at choosing a low-cost and environmentally friendly fuels boiler. The quality of the steam plays a decisive role in the quality of products dyed and dried in clothing and textile factories. The textile industry also consumes a large amount of fuel for steam boilers, so choosing the right steam boiler can not only effectively improve the quality of textiles and production efficiency of textile enterprises, but also reduce labor costs and operating costs of steam boilers. The company established a cooperative relationship with us for one 6-ton SZL series biomass fired chain grate steam boiler through market and online search. And the customer choose wood chips as boiler fuel, which can effectively reduce the operating costs of the enterprise. The application of XINLI Boiler SZL biomass steam boiler by this textile enterprise not only brings dual benefits in terms of environment and cost, but also sets a benchmark for its green transformation to promote the company's progress towards clean production.

This 6 ton of SZL series biomass fired chain grate boiler from Xinli Boiler adopts advanced water-cooled wall technology, which can ensure the stability of steam quality, avoid the problem of high or low steam humidity, but also ensure the stability and quality of customers' textile production processes. In addition, Xinli Boiler's biomass fired steam boiler has also innovated in intelligence by being equipped with an intelligent monitoring system that can monitor and provide real-time feedback on the boiler's operating status, fuel usage, emission data, and more. The intelligent system not only simplifies the operation and management of the boiler, but also automatically adjusts the combustion mode according to the load demand, thereby further reducing energy consumption and ensuring the stable operation of the equipment. The application of this intelligent control not only improves energy efficiency in the production process of enterprises, but also reduces manual maintenance costs and equipment wear, prolongs the service life of equipment, and brings long-term economic benefits to the green transformation of enterprises. The Xinli Boiler SZL biomass fired chain grate steam boiler has demonstrated extensive adaptability in various industries such as textiles, food, and papermaking. Its stable performance and environmental protection effects have been recognized by multiple enterprises. Xinl Boiler is injecting new impetus into the green transformation of various industries, leading the field of thermal equipment towards a more sustainable, low-carbon and environmentally friendly future through continuous exploration and technological innovation.

More information on Facebook:

https://www.facebook.com/Xinli.Boiler.Co/posts/pfbid02HfynqGW8VqUB87KffuCo1mhATwFYuxrUm7sMcaATQEyNzE4vDkBd2oF5iQJx2F5pl

Email: [email protected]

Email: [email protected]